Describing the NSP content of raw materials is fundamental to our understanding of dietary fiber and how to deal with its negative consequences.

The ability of pigs to digest more fibrous diets without compromising productive performance is fundamental to improving opportunities to reduce cost per kg gain in the current economic environment. However, there are many performance challenges that come with adding dietary fiber, including satiety, gut motility, nutrient digestion and absorption and changes in the gut microflora that could impact animal health.

Improving the feeding value of fiber-rich raw materials is consequently about negating the anti-nutrient effects of dietary fiber to ensure that animal performance is maintained or improved, but at lower cost. Dietary fiber is nowadays more precisely defined as “non-starch polysaccharides [NSP] + lignin” (Figure 1), and understanding the fiber fraction of individual raw materials, and its inherent variability, is very important when designing diets to maximize pig performance. The term “crude fiber” (still present on many feed labels around the world) is predominantly only a measure of cellulose plus lignin and consequently itself is a very crude, inaccurate measure of fiber content and its likely effects on animal performance. Other factors in dietary fiber, e.g. its hemicellulose content (Figure 1), and, more specifically, its NSP content, are far more influential on nutrient digestion and absorption in the animal’s gut.

Pigs feeding on more fibrous diets have to overcome a number of challenges. These include: extra chewing of certain fibrous raw materials; increased endogenous losses as a consequence of more salivary, gastric and pancreatic secretions; increased gut weight stimulated by the presence of more fiber in the diet over time; and changes in digesta transit time, often governed by the balance between soluble and insoluble fiber in the diet. More fibrous diets also have the potential to increase fecal volume, which will have ultimate implications for the costs of manure management. This can be a further challenge, particularly in some areas of the world.

Pigs feeding on more fibrous diets have to overcome a number of challenges. These include: extra chewing of certain fibrous raw materials; increased endogenous losses as a consequence of more salivary, gastric and pancreatic secretions; increased gut weight stimulated by the presence of more fiber in the diet over time; and changes in digesta transit time, often governed by the balance between soluble and insoluble fiber in the diet. More fibrous diets also have the potential to increase fecal volume, which will have ultimate implications for the costs of manure management. This can be a further challenge, particularly in some areas of the world.

The net effect of all the above is a potential increase in maintenance energy and protein costs to the animal when feeding more fibrous diets, so any solutions we propose must be able to offset these negative effects.

The case of arabinoxylan

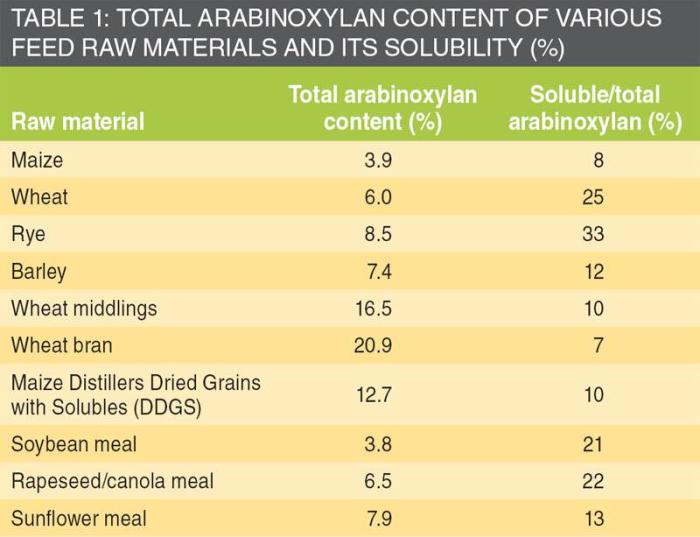

Fibrous raw materials (e.g. grain by-products) offer interesting opportunities to save feed costs in pig rations, but their high fibre content is a potential challenge to nutrient availability and consequent pig performance. Arabinoxylan (Table 1) is a key component of the NSP content of many raw materials and it varies in its solubility. Soluble arabinoxylan in raw materials such as wheat and rye (approximately 30 percent of the total arabinoxylan present, Table 1) is the reason for the “viscous” nature of these grains when present in the gut. This viscosity effect, although less detrimental in pigs than poultry, can still negatively influence the gut microflora in terms of its content and composition. Currently, and especially in the U.S., other arabinoxylan-rich ingredients are receiving much attention, namely: maize distillers dried grains with solubles (DDGS) and wheat middlings (Table 2).

Dealing with the fiber challenge with exogenous enzymes

One way to deal with arabinoxylans is using exogenous enzymes, and early experiences are promising, yet, not all xylanase sources are equal in efficacy at the pig gut level. Independent trials in Denmark over several years by Videncenter for Svineproduktion (VSP) have highlighted interesting differences between various xylanase products in terms of their effects on grower-finisher pig performance and their consequent economic benefits.

The economic effects in each trial are difficult to directly compare across various years because of the varying assumptions made about feed prices (e.g. much more expensive feed costs in recent years) so the fairest comparison is in terms of percentage benefits in feed conversion ratio and their economic significance at the time that each trial was run (Table 3).

The results over time show clear differences in bio-efficacy between the various xylanases. Each xylanase source has its own unique characteristics (e.g. pH optimum, temperature optimum, rate of reaction according to substrate level, sensitivity to endogenous secretions) so it should be no surprise that different products will vary in bio-efficacy.